Innovative technologies for conservation & athermal decontamination

Innovative technologies offer many benefits: improvement of organoleptic quality, decontamination of dry products, decontamination at low temperature... Our pilots and partners allow you to test different matrices and parameters on your applications, on wet or dry products.

Evaluation of decontamination efficiency (all technologies)

You have designed an innovative technology or want to test an existing one, classic or innovative?

Install your equipment in our halls, our food production conditions and our laboratories will allow you a factual evaluation of the impact of this technology and the achievement of your objectives (challenge tests and microbiological, organoleptic, nutritional, sanitary type neoformed...), formalized by a CTCPA report. We also carry out evaluations on your lines.

We assist you in filing Novel Food files or usage applications when this is a regulatory requirement.

Pulsed light

Pulsed Light is a highly promising decontamination technology for food processing. The CTCPA and Claranor have joined forces to help food processing companies identify and develop new applications for sustainable Pulsed Light treatment. This water- and chemical-free, low-energy technology has proved its worth in packaging treatment, helping to reconcile ecology and economy. The CTCPA and Claranor offer food companies the benefit of their respective expertise and the impartiality of the CTCPA technical center for R&D studies, including equipment rental if required.

Some applications may require the preparation of ausage authorization or novel food file for which we are able to assist you.

Assistance in the choice of technologies and tests in pilot halls

Testing and helping to choose innovative technologies are at the heart of our missions. Come and test tomorrow's technical solutions in our halls or those of our partners, for dry or wet products, pumpable or not.

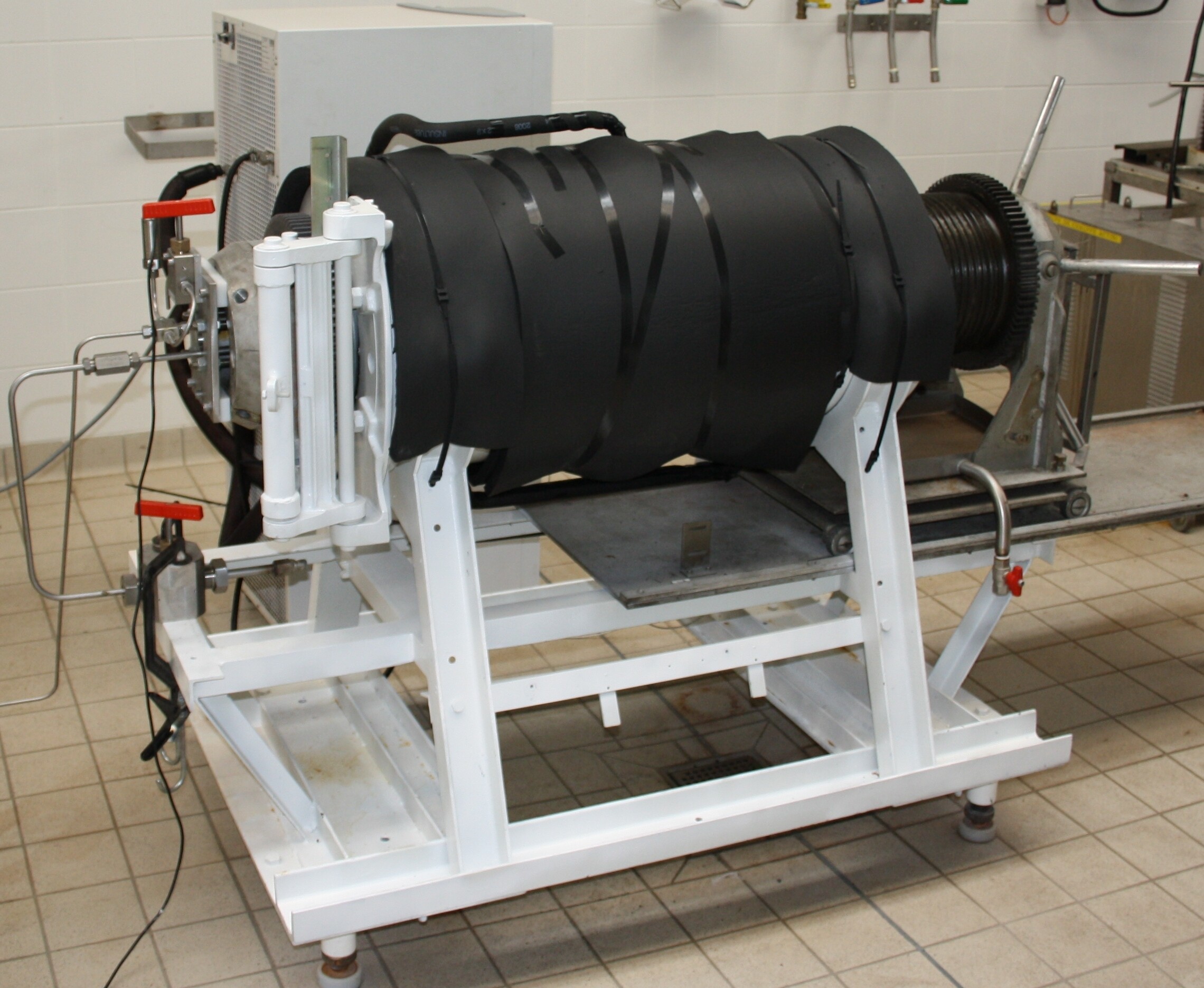

High Pressures

High pressure treatment allows to decontaminate products by applying pressures up to 6000 bars. The pressurization is instantaneous within the hyperbaric chamber.

The treatments are fast with a low environmental impact. The other interest is the preservation of nutritional and organoleptic characteristics.

- Possibility to increase the life span of your products by preserving the naturalness of the products, avoiding or reducing the need for preservatives (lighter labels, "clean label" approach).

- Secures products by destroying pathogens (Listeria, Escherichia coli, Samonella spp., Vibrio, norovirus, ...). This process is recognized as Listeria free in the USA.

- Possibility of carrying out challenge-tests to verify the effectiveness of the process on your products.

Tools: in connection with HPP Atlantique, a 100-liter pilot + a laboratory pilot in Avignon

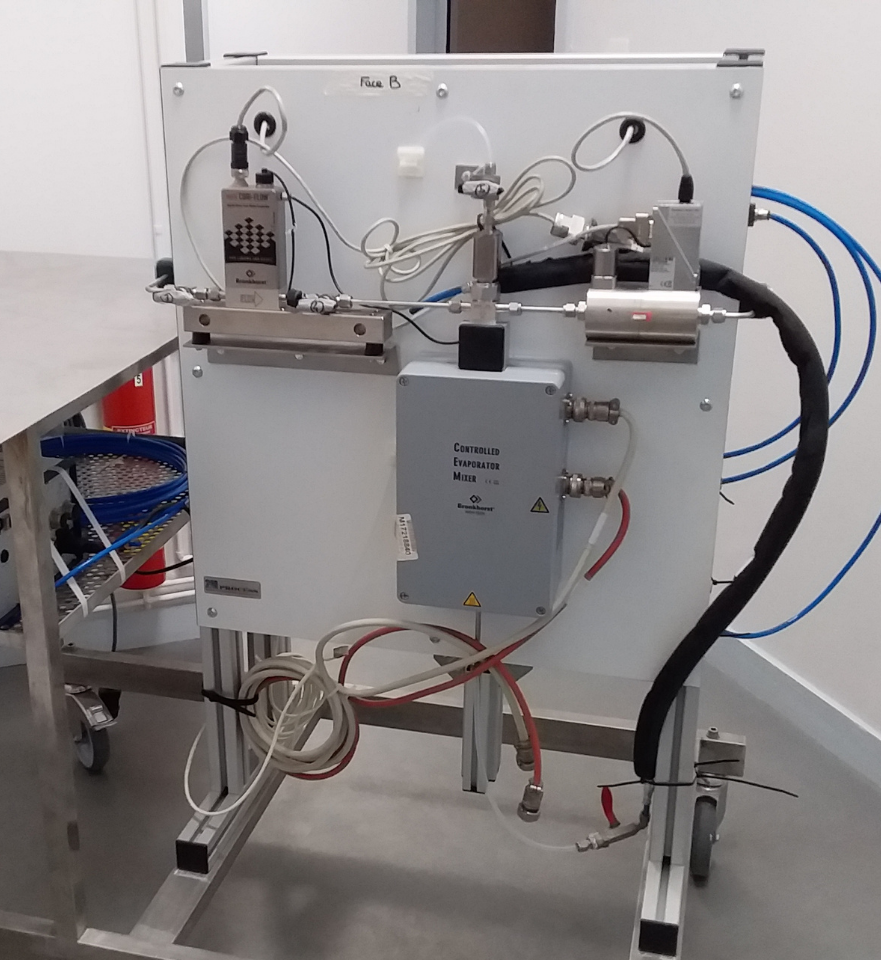

COLD DECONTAMINATION BY OXIDIZING STRESS: Ozone, hydrogen peroxide vapor (HPV), peracetic acid (PAA), H202, Chlorine (Cl2)...

The CTCPA has its own pilots or pilots with its partners to test various technologies of decontamination by oxidative stress at cold or low temperature:

- Gaseous: Ozone, hydrogen peroxide vapor

- In liquid way: Peracetic acid, H2O2, Cl2, Bromine...

Oxidative stress technologies are classified as processing aids, and are particularly interesting for the decontamination of dry products by gas. We can evaluate the decontaminating impact thanks to our challenge test.

Some applications may require the preparation of ausage authorization or novel food file for which we are able to assist you.