Our food processing equipment

The CTCPA has €6 million worth of state-of-the-art agri-food equipment!

The CTCPA has access to 4 technology halls located in the region – Avignon: CTCPA hall, Nantes: Oniris hall, Auch: CTCPA hall, Beauvais: FoodLab. The CTCPA also has 3 laboratories: Microbiology/Molecular Biology, Nutritional Quality, Packaging. Discover below some examples of our equipment!

Innovative technologies

The CTCPA (Technical Center for the Conservation of Agricultural Products) invests in the latest technologies for the processing and stabilization of food products.

These technologies are qualified and mastered by our teams:

- Ohmic heating

- Latest generation microwave tunnel

- Decontamination by oxidative stress (Hydrogen Peroxide Vapour HPV)

- High Pressure Treatment

- Pulsed Light Pilot

Innovative technologies offer many benefits: improvement of organoleptic quality, decontamination of dry products, decontamination at low temperature... Our pilots and partners allow you to test different matrices and parameters on your applications, on wet or dry products.

OHMIC HEATING

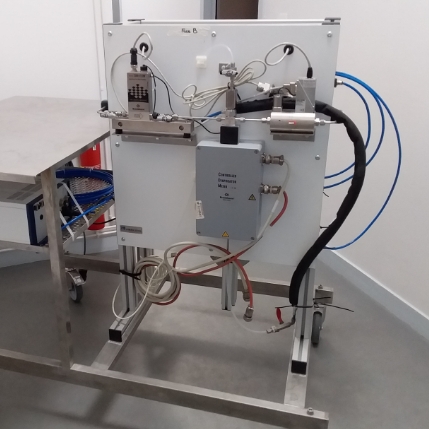

HPV PILOT

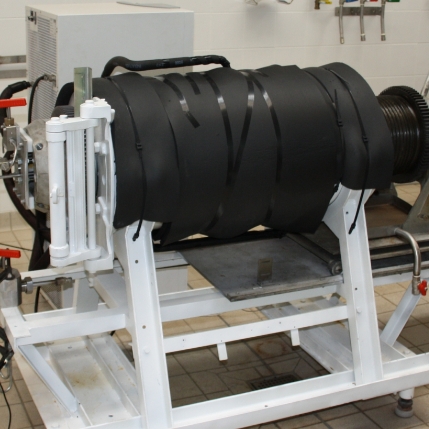

MICROWAVE TUNNEL

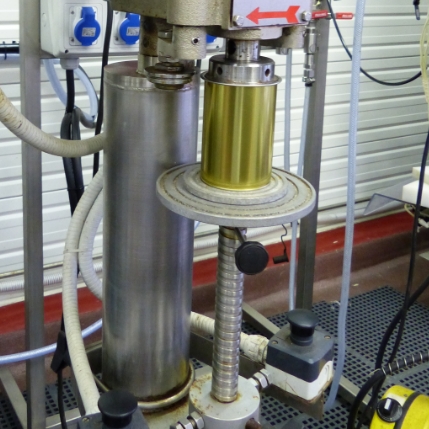

HIGH PRESSURE

CUVE

CUTTER

COOKING VESSEL

PRESS-JUS

Preparation and mixing material

With a wide range of equipment available in our technological halls, the CTCPA is able to reproduce on a pilot or semi-industrial scale the transformation processes of all types of food products:

- washing

- trimming

- cutting

- grinding

- mixing

- cutting

- ...

The materials are arranged on request to design custom lines.

Thanks to the specialized skills of our teams and our state-of-the-art equipment, we can help you create and optimize your production processes. Pilot trials in our technology halls, feasibility studies, tests of innovative technologies: we help you find the best techniques and processes adapted to your company and your project.

Heat treatment

The application of heat treatment to ensure the preservation of products can be done in many ways at the CTCPA:

- In a small-scale or semi-industrial autoclave, depending on the technical nature of the product and the volumes involved, for packaged products,

- In continuous exchangers for pumpable products: tubular, annular, with a grated surface, with plates; with aseptic packaging downstream from the treatment.

Drying and freezing/mechanical freezing equipment are also available in our halls.

The main objective of heat treatments is to destroy the reproduction capacities of microorganisms by heat, in order to ensure the conservation of products at room temperature in complete safety. The CTCPA helps you to define the optimal and specific scale for each couple product / packaging which is essential to guarantee a safe treatment (microbiological quality) and optimized (organoleptic quality). Heat treatments also allow to destroy enzymatic activities to stabilize products or to reach a certain degree of cooking. Pasteurization, sterilization, microbiological stability control, ohmic heating, development of isobaric scales, microwaves: we help you optimize your heat treatment scales to improve the organoleptic and nutritional qualities of your products, reduce processing times and cut energy consumption. We use our software Stéri'Opt.

The CTCPA is recognized by the DGAl (DGAL/SDSSA/N2011-8153) as the reference center for the validation of scales.

ARTISANAL AUTOCLAVES

INDUSTRIAL AUTOCLAVES

WHITERS

TUBULAR EXCHANGERS

SCRAPED SURFACE HEAT EXCHANGERS

FREEZING / DEEP-FREEZING / COOLING CELLS...

COOKING CELL

ATOMIZATION

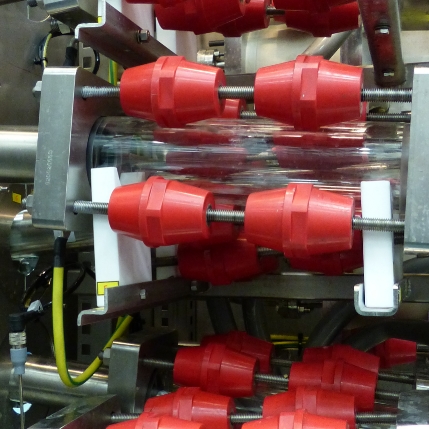

SERTISSEUSES

BARQUETUSES

CAPSULEUSES

SUB-VIDE

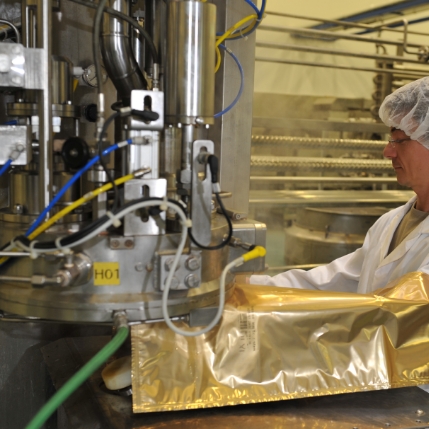

ASEPTIC HEAD

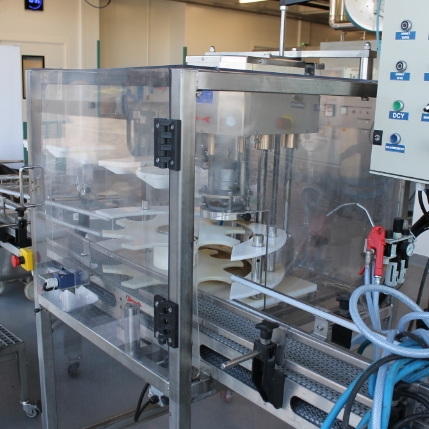

Packaging

A wide variety of formats and types of packaging can be closed in our halls:

- bottle

- glass jars

- metal cans

- trays

- aseptic bags

- bowl

- cups.

Product characterization

Various characterization equipments allow to establish the thermal and physico-chemical properties of the processed products:

- temperature

- texture

- pH

- Aw

- viscosity

- ...

The control of the tightness of the packaging and the accuracy of the measuring instruments is also carried out.

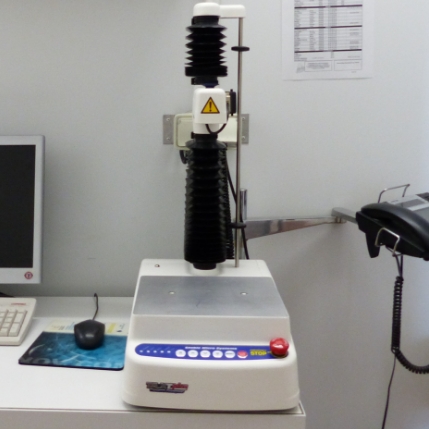

CRIMPING CONTROL

OIL BATH

TEMPERATURE CONTROL BY WIRED SENSOR

ON-BOARD SENSOR PARK

TEXTUROMETER

CALIBRATION BATH