Packaging performance control and defect diagnostics

Packaging performance: The functionality of packaging implies the control and mastery of barrier performance, mechanical performance in all conditions of use as well as other functions, from the good transformability of packaging in the packaging workshop to consumer convenience evaluations.

Gas transfers: permeability and leakage

We carry out your leakage and permeability tests on finished packaging (taking into account packaging defects) and in real conditions, taking into account the effects of temperature and humidity.

We identify the most relevant tests according to your uses, the uses of your customers or within the framework of customer/supplier disputes.

Learn more on our packaging website.

Mechanical performance

We carry out mechanical performance tests of your packaging in their conditions of use: drop, compression, traction, punching, tearing... and in multiple environmental conditions, including temperature and humidity.

Learn more on our packaging website.

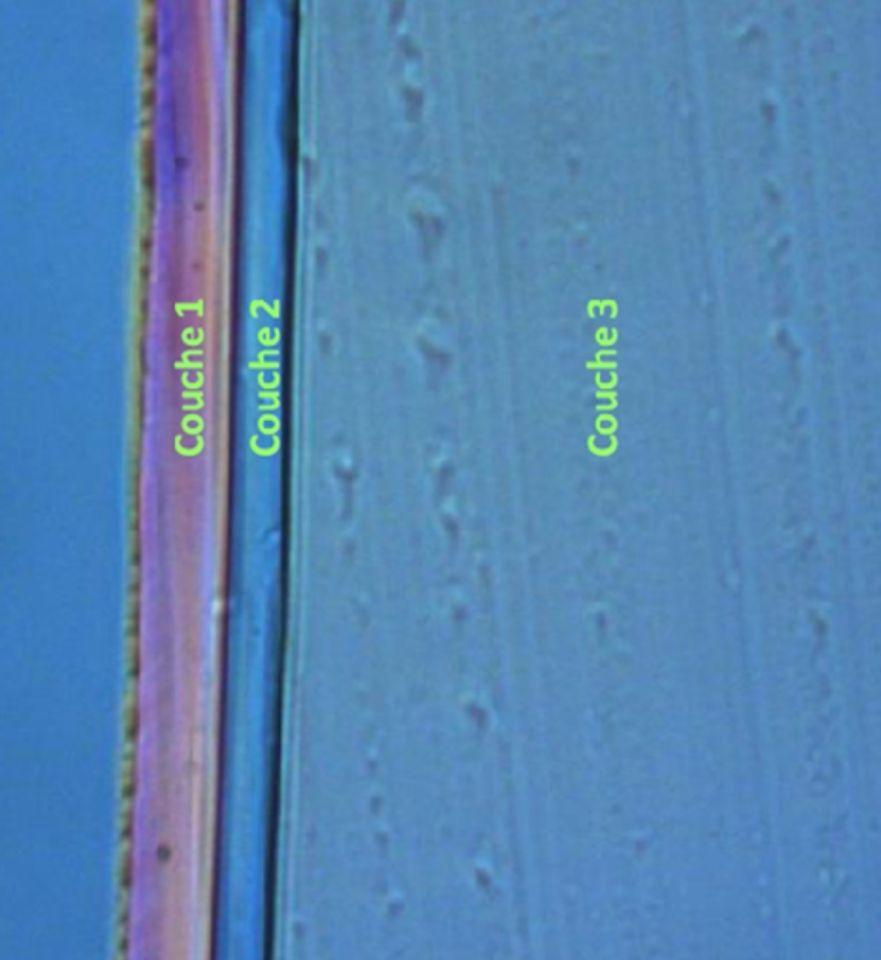

Control of multilayers, sealing problems

We have at our disposal a wide range of tests allowing us to identify the sources of defects in the quality of the sealing of your packaging:

- Thermal analysis

- Laboratory sealing control tests

- Delamination or bursting tests

- Microscopy analyses

- Evaluation audit of the packaging line

Beforehand, we carry out an initial diagnosis by measurement (leakage test) and localization of defects by visual observation or microscopy: thermal analysis, control tests of sealing in laboratory, delamination or bursting tests, microscopy analysis (visible, FTIR, SEM), evaluation audit of the packaging line

Learn more on our packaging website.