Definition and development of the production process

Thanks to the specialized skills of our teams and our state-of-the-art equipment, we can help you create and optimize your production processes. Pilot trials in our technology halls, feasibility studies, tests of innovative technologies: we help you find the best techniques and processes adapted to your company and your project.

Pilot tests, comparison of technologies, technical feasibility studies

Come and carry out your tests in our food processing halls in order to define your optimal process from a technical and economical point of view.

We offer you :

- Pilot test on a technology

- Comparative tests of several technologies

- Product characterization (color, texture, microbiology, micronutrients...).

You will be able to test preparation technologies (cooking, extraction of puree or juice, concentration...), packaging (aseptic or classic, in trays, bags, doypack...) and preservation (cold, hot, physical, chemical, combinations and hurdles...).

Our equipment allows us to reproduce the vast majority of manufacturing processes in the food industry (excluding cheese technology and alcoholic fermentation), including aseptic processes.

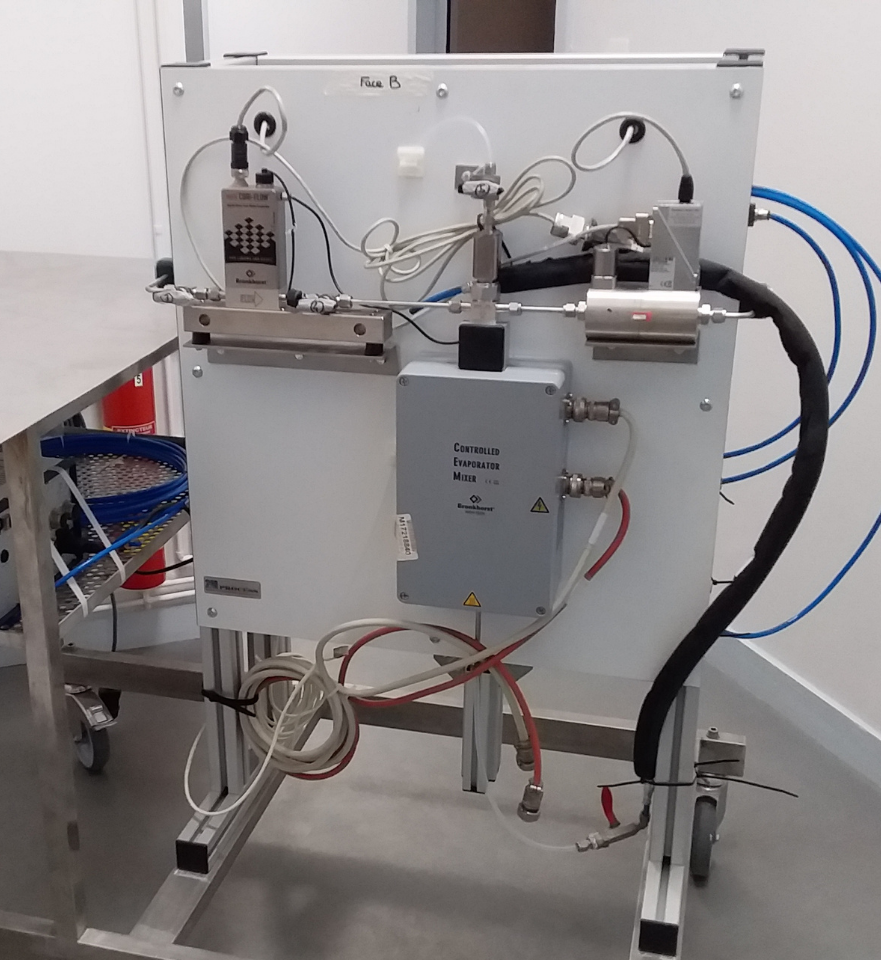

Testing of innovative technologies

Come and test in our halls or in those of our partners the different production processes of tomorrow for dry or wet products, pumpable or not.

Our materials:

- ohmic heating (see our video on this technology)

- high pressures

- microwave pasteurization

- cold or low temperature decontamination by gaseous or liquid Ozone) or hydrogen peroxide vapor

- decontamination by oxidative stress in liquid (APA, H2O2, Cl2, ...)

- pulsed light

- Hurdles and combinations of technologies

Evaluation of decontamination efficiency

You have designed an innovative technology or wish to test an existing one?

Install your equipment in our halls and have a factual evaluation carried out of the impact of this technology and the achievement of your objectives.

Our microbiology team also carries out process challenge tests.

We can also, if you wish, carry out these evaluations directly on your lines. Each evaluation is formalized by a CTCPA report.

Furnace management: audit, mapping, training...

Are you an industrial cookie or pastry manufacturer, or do you have a process using a tunnel oven? Are you looking for a better understanding of how your oven works, or how to improve your finished products? Have you just acquired a new oven or are you integrating new staff?

CTCPA can help you :

1) Line audit following production irregularities on finished products (colouring, thickness, humidity, etc.) The objectives are :

- Understand the effects of changing oven settings (e.g. temperature difference between zones, % air extraction, etc.) on the oven atmosphere (T°C and humidity).

- Test and validate hypotheses using oven mapping to understand critical process factors affecting product quality

- Capitalize on and formalize best practices in furnace operation (depending on the situations encountered).

2) Receiving a new oven or integrating new employees:

- Training teams to understand and master furnace operation (theoretical and practical part over 2 days)

- Oven mapping