Food microbiology: a 350 m² laboratory

We have acquired expertise in the control of microbiological risk in foodstuffs at each stage of their production: raw materials, manufacturing, processing, conservation. In our food microbiology laboratory and our molecular biology laboratory, we provide various services to support you in the development of your products.

Contact : microbiologie.contact@ctcpa.org

Product and process test challenges

On YouTube: [Food microbiology] Product and process test challenge

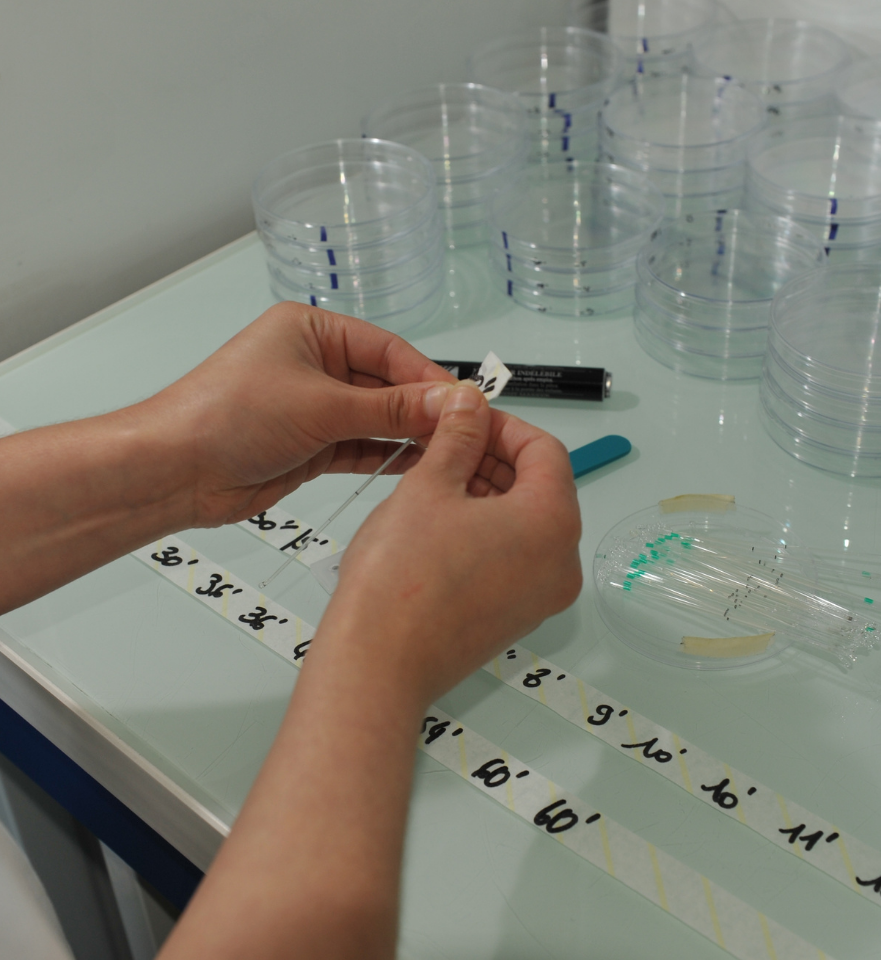

Our challenge tests are carried out in our P2 laboratory in Avignon. These challenge-tests can be standardized or non-standardized, if you require greater flexibility!

How do we proceed? Before the challenge-test, our microbiologists meet with you to define your project. Once the challenge-test has been carried out, our experts interpret the results and debrief with you!

- The PROCESS" CHALLENGE-TEST is designed to measure the effectiveness of a treatment. It consists in voluntarily inoculating a micro-organism and measuring the microbial population differential before and after treatment. It is carried out in accordance with ISO 20976-2 standard in 2 ways:

Determination of inactivation at T0

Kinetics of inactivation over time.

In the 2nd case, the effect of a preservative or a molecule replacing the preservative can be studied.

The CTCPA advantage Our microbiologists are at the heart of the field, working directly with our technologists in our pilot plant. Treatments can therefore be submitted directly on site!

- The PRODUCT" CHALLENGE-TEST is used to assess the growth potential of micro-organisms on a product during storage under normal conditions after opening. It is carried out in accordance with ISO 20976-1.

Challenge tests are not compulsory, but are highly recommended, especially for pathogenic microorganisms with low prevalence. They are an interesting tool for determining shelf-life. The CTCPA is recognized by the DGAL(DGAL/SDSSA/2019-861 24/12/2019) to assist manufacturers with their shelf-life validation dossier.

The CTCPA advantage The CTCPA laboratory is recognized by the DGAL(DGAL/SDPPST/N2013-8200) to carry out challenge tests for Listeria monocytogenes.

Microbiological studies

The CTCPA carries out all types of microbiological studies, relating to products (e.g. study of shelf-life extension, choice and efficacy of preservative ingredients, microbial evolution of native flora, etc.) or processes (impact of a process, comparison, etc.).

Our studies are conducted by a microbiologist and, if necessary, by a specialist in processing or decontamination procedures, for example.

The CTCPA advantage A link with the application, thanks to our knowledge of products, processes & equipment and packaging, beyond microbiology. Our technology hall is housed in the same building as our laboratory.

Process validation and hygiene improvement

On YouTube: [Food microbiology] Process validation and improvement

- Microbiological audits / line accidents (sampling, identification of fouling points, etc.)

The CTCPA can help you find the cause of non-conformities through in-depth expertise, by isolating the microorganism(s) responsible and identifying them by molecular biology, in order to propose targeted corrective actions. The identification of all types of germs can be carried out in different ways, including 16S sequencing, or for spores using our SporeTraQ* Thermophilic, Mesophilic and Psychrotrophic methods.

SporeTraQ: Bacillus licheniformis, Bacillus coagulans, Clostridium thermopalmarium, Morella Thermoacetica, Geobacillus stearothermophilus and Thermoanaerobacterium spp, Clostridium sp psychrotrophes and Clostridium algidicarnis.

- Decontamination verification studies

The CTCPA uses its own methods: inoculated coupons placed in your processes to check that they are destroyed correctly.

- Cleaning-disinfection studies, hygienic design and process validation (in conjunction with our EHEDG-qualified experts)

On your site, we carry out line assessments (asepsis, cleaning & disinfection, decontamination efficiency, etc.), in the form of diagnostics with samples (water, surface, air, in-process food, etc.) to measure efficiency and identify areas for improvement. This diagnosis is carried out by our experts, including EHEDG-qualified experts.

These evaluation and analysis operations enable you to continually improve your processes and product control. These operations can also include validation of product heat treatment or disinfection schedules (including in continuous technology with integration of the effect of residence time distributions, the use of seeded biotests or alginate beads).

Hygienic design / Optimized cleaning and disinfection

Optimal hygienic design reduces cleaning and disinfection time and frequency.

Our certified specialists, members of theEHEDG, come to your company to help you with your projects to create a new workshop or optimize an existing line.

Resolution of microbiological manufacturing incidents

The CTCPA is your partner in the event of a microbiological incident!

When faced with a microbiological incident on your food production lines, the CTCPA offers a complete solution tailored to your needs.

- Fast, efficient response : our teams intervene as quickly as possible to limit contamination and losses.

- Analysis of causes and implementation of corrective measures: our experts identify the source of contamination using their analytical tools (surface sampling, analysis, PCR, challenge tests, inoculated coupons, etc.) and implement corrective measures to prevent recurrence.

- Support in monitoring and prevention: we support you in monitoring the situation and implementing preventive measures to avoid further incidents.

Our team of experienced specialists is on hand to answer your questions and offer you a solution tailored to your situation.

Analysis (stability, sterility, etc.)

On YouTube: [Food microbiology] Stability tests and non-stable assessments

- Stability tests

Stability tests are designed to measure a food's stability before it is put on the market. We use the following stability standards NF V08 401 (reference standard) and NF V08 408 (routine standard). As part of our R&D, we are now adapting these standards for very acidic or acid/sweet products (low Aw), to improve the detection of microorganisms more specific to these products.

- Sterility tests

In some cases (food intended for infant feeding or for the nutraceutical field, or for the French armed forces), sterility tests are required and carried out by our team using internal methods.

- Other analyses

The CTCPA performs many food analyses of expertise, on all types of flora with an important know-how in the field of heat-resistant germs.

The CTCPA advantage Our staff are available to interpret results for our customers.

Leak and crimp analysis

The analysis of leaks and crimps enables us to incriminate or exclude this path in cases of non-compliance. We can also help you with :

- Determining the spore load in raw materials

- Qualify cleaning/disinfection operations

- Diagnose your line.

We determine spore load using the NF V08-602 standard (ISO standard currently being drafted) for spores of mesophilic and thermophilic bacteria.

We also enumerate spores of psychrophilic/psychrotrophic bacteria using an in-house method, for pasteurized products.

The CTCPA advantage Our staff are available to interpret results for our customers.

Expertise on non-stable canned goods

The CTCPA offers expertise in non-stable canning, the core business of the technical center.

The aim is toidentify the microorganism responsible for non-stability, its origin and the possible causes of its presence in the appertized product. The causes of the observed non-stability must be elucidated.

In addition to the identification of strains, the protocol implemented calls for various expert assessments, including examination of crimps and package tightness (only for non-stability observed at 37°C, 32°C and room temperature).