Training - Key points in industrial canning

The CTCPA, Centre Technique de la Conservation des Produits Agricoles, offers you a training course to learn the key points of industrial canning.

CTCPA PEDAGOGY

- Acquire knowledge specific to appertization to be able to carry out a technical function in a canning facility.

LEARNING OBJECTIVES

- Active and participative pedagogy.

- Exchange of experiences and discussions.

- Presentations, slide shows, practical exercises.

- Evaluation of the course by the trainees.

- Evaluation of the trainees' knowledge by questionnaire or case study

- Provision of documentation and training materials.

- Issuance of a certificate of training

TEACHING METHODS

- Context and regulations relating to sterilized products

- Manufacturing processes: stages in the manufacturing process for canned products. Formulation issues, acid and non-acid products

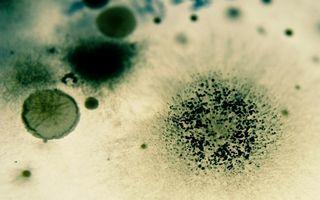

- Notions of microbiology: spoilage and pathogenic flora, spore-forming and vegetative flora, toxins; development conditions.

- Heat treatment: sterilization/pasteurization schedules

- Heat treatment equipment

- Packaged in metal and/or glass cans

- Finished product controls

- Practical work (on site or in the CTCPA hall)

Content of the training

Are you recruiting new staff who are familiar with the food sector but have never worked in a cannery?

Do your current employees need to reinforce their knowledge to better understand their position?

As a specialist in acid sterilized and pasteurized products, the CTCPA offers a 3-day training course on the key points of appertization, to help you understand the ins and outs of the process, and identify the points to watch out for, which are essential to ensure a reliable manufacturing process.

Discover our other training courses: Food industry training courses, a comprehensive training catalog, CTCPA